Most of the people that know me also witnessed of my long-running passion for motorcycles and the Italian brand Ducati in particular. For all my sins, I also like to reflect on various experiences in life and relate them to my work interests in digital leadership, change management and team coaching. As it happens, riding a powerful motorcycle has much in common, and I thought about capturing it in this blog.

How to integrate and apply counter-intuitive practices?

The first and most fundamental learning of riding a motorcycle is countersteering. If you want to turn right, at speed, you push on the right side of the handlebars as if you were steering to the left. Likewise, if you’re going to turn left, you push on the left-hand side of the bars. Many of you will not believe me on this one, and please ask any biker to confirm if you are not ready to take my word for it. Countersteering is counter-intuitive, and it messes with your head for a while before you master the practice as a skill. Once you do get it, you actually exploit the technique to turn quicker. There is a logical explanation for it. A motorcycle requires leaning to turn. Countersteering breaks the centrifugal forces of the motion of the wheels and allows the bike to lean. A 200kg motorcycle launched at triple digits speed (on a race track obviously) is like on rails. It only wants to carry on straight. Let me tell you, it is strongly advisable to have recalibrated your brain to this skill when you are about to attack the Craner Curves at Donington.

I would compare countersteering to the mindset shift that it takes to move from traditional scale economics to lean-agile flow economics in the enterprise. There is a logical explanation to adopt flow economics. As projects span across the verticals of the enterprise, dependencies result in much wait time, delays and waste. Shifting from a vertically aligned organisation to a horizontally aligned organisation to improve flow requires much recalibration. Only education and practice overtime will convince of its worth.

Look where you want to go!

Another fundamental principle of riding is that the bike will steer where you look. If you have an obstacle in front of you, target fixation is a guaranteed crash. You need to look at the escape route, not the problem. This principle is again much easier said than done when travelling at speed. I remember a club’s mate crashing inches from my front tyre at Clearways in Brands Hatch, and it was a close shave avoiding him. During that split second, I had to force my brain to guide my eyes towards the solution, not the problem.

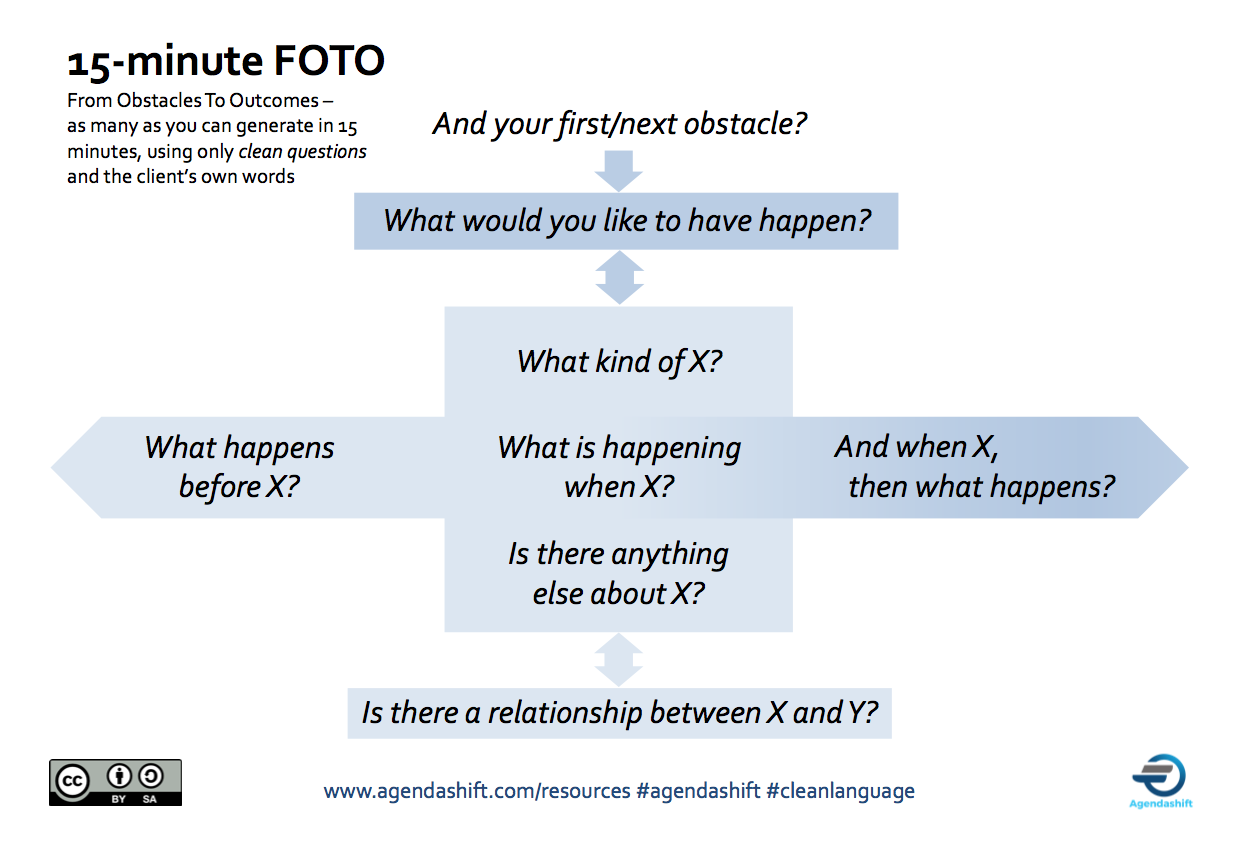

The same applies in business. Too often we fixate on problems rather than look for solutions. Lean has a wealth of tools to analyse issues, such as the fishbone diagram and the Five Whys. Causality is not always evident however. In Complex environments, causality can be multi-faceted or even non-existent. The same causes will not have the same effects. It is essential to recognise such situations, avoid the target fixation on the problem and pivot to the possible solutions. Mike Burrows from Agendashift has an excellent FOTO exercise: From Obstacles To Outcomes. Applying a set of “Clean” questions turns challenges into outcomes that we would like to have happened. It helps the teams organise around solutions.

Agendashift 15 min FOTO exerciseAgendashift 15 min FOTO exercise

15 min FOTO exercise from Agendashift. Please see more at: https://www.agendashift.com/15-minute-foto

Anticipation and planning allow dealing better with the unknowns and are a dynamic exercise

Keith Code was the guru at the origin of the excellent California Superbike School. One of his teachings was that you would enter every turn with $10 worth of attention. If you planned your turn in your head (braking point, turning point, apex, vanishing exit point), your brain would only consume a few $$ to negotiate the turn. If an issue occurred mid-way through the corner, you would have some spare $$ to deal with it. On the other hand, if you did not plan, you would spend your $10 through the turn, figuring it all out as you went along. If any issue occurred, you would have no more $$ to address it. If you ran out of $$, you generally ran out of tarmac too. Badaboom!

In business it is similar. You need enough of a plan so you can handle variability. But you don’t want to spend your $10 before you even arrived into the corner. No plan and you won’t be able to handle variation. Too much of a plan and you would have no capacity left to adapt either. I would recommend reading some of the work of Mary Poppendieck on the subject of planning, notably how the Empire State Building was build in 18 months, thanks to a combination of scheduling and flow.

Finding your flow, going slower to go faster

Riding a motorcycle offers a magical experience. Once you get in the flow, you get in the “zone”. You go from turn to turn, from braking point to apex to acceleration out. Your movements are anticipated, coordinated, it feels slower. Then you look at your lap time, and you were going faster. On the road, you achieve this slightly differently. Unlike track riding, you do not cover the same ground lap after lap. You have to compose with unexpected conditions like traffic, changing road surface or the changing radius of some turns. In those conditions, it is utterly silly to ride on the edge. You have to factor in some room for the unexpected. You are much slower (and responsible), but your attention to reading the road is just as intense. There are more elements to compose with, and an equal satisfaction comes from achieving this flow of riding.

The riding conditions that I am describing above are not that different from what the Cynefin framework describes as Ordered Domains (track riding) and Complex Domain (road riding). In the ordered domains, there is less variability. You can optimise lap after lap. In the Complex domain, the circumstances change, and you have to adapt continuously. Variability gets handled differently. You compose with it all the time. Either way, achieving flow is the ultimate experience. Flow can always be improved. Using Kanban techniques such as controlling your WIP (Work in Process), appears slower initially. Eventually, you get the flow, and you get faster. Focusing on improvements also keeps you clear from complacency. Complacency causes accidents, on the road and in business.

Be engineering minded and respect your engineers

A biker has mechanical sympathy, and a good biker has sympathy for his mechanics too. It does not take much, I have the simple routine of washing my bike thoroughly before taking it to my mechanic. It is a question of respect. In turn, a mechanic will take better care of a well looked-after motorcycle. I am also forever thankful to the mechanic that allowed me to spanner alongside him so that I could understand the inner-workings of a Desmo engine. From this, I realised how crucial preventative maintenance was. Though I grew hands-on competence myself, the understanding of the engineering and the work is more what mattered. I kept going to him so that I could learn more. Riding a motorcycle at speed, you are very vulnerable. Beyond trust in your riding skills, you have to trust the machine and the mechanics that look after it. I cannot stop admiring the incredible courage or madness of the Isle of Man TT racers. Their commitment is total, riding at average speeds of over 130 mph, around the Island roads, going through regular country roads and villages turned into a race track for the time of the TT week. The smallest mistake is often fatal. Trust in their mechanics they have.

The same mutual respect, trust and commitment should take place in the place of work. We should learn to appreciate the quality of a well-engineered application and respect the work of the team that put it together. It does not require the manager to have all the skills to do the job hands-on. But it demands that management and business alike improve their understanding of the technical engineering, at least enough to make the right calls, and never put the team in a position that they have to compromise quality. The manager can only achieve this by being active with the teams. Lean in its early form of Toyota Production System was insistent on “Gemba,” which stands for visiting the place of work. Active participation in Kaizen (the process of continuous improvements) is also a right way of connecting management to the day-to-day reality. There are no metrics and dashboards that can replace conversation and involvement to achieve this shared understanding and trust.

This article was meant to be light summer writing for light summer reading. I hope that it provided some compelling parallels and would open horizons, both on applying those principles to your Digital change management efforts as well as on developing your interest in the intricacies of riding motorcycles.

Sources:

Keith Code – book The Twist of the Wrist

Agendashift – https://www.agendashift.com/ and https://www.agendashift.com/15-minute-foto for the 15 min FOTO

Clean Language – https://www.cleanlanguage.co.uk/

Mary Poppendieck – http://www.poppendieck.com/

Cynefin Framework – http://cognitive-edge.com